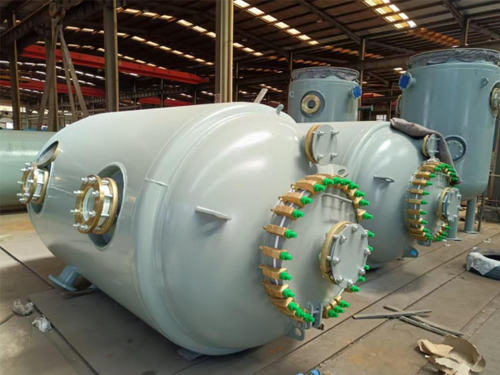

Standard Operating Procedure (SOP) and Critical Safety Protocols for Glass-Lined Reactors

Introduction

The

exceptional service life of a Glass-Lined Steel (GLS) reactor is

contingent upon strict adherence to correct operating procedures. Due to

the brittle nature of the glass lining, deviation from SOPs can lead to

costly damage. This article outlines a safe and effective framework for

operation.

Standard Operating Procedure (SOP)

Phase 1: Pre-Operation Checks

Visual Inspection: Confirm the vessel interior is clean, with no chips or cracks in the glass. Ensure agitator blades and baffles are secure.

Seal System Check: Verify mechanical seal flush lines are open and pressurized (if applicable). For gland packing, check for proper adjustment.

Utility Verification: Ensure all services (cooling water, steam, nitrogen, vacuum) are available and connected to correct ports.

Instrument Calibration: Confirm temperature probes, pressure gauges, and level indicators are functional and calibrated.

Dry Run: Briefly jog the agitator to ensure it rotates freely without contact with baffles or thermowells.

Phase 2: Charging, Reaction, and Control

Charging Materials:

Solids: Introduce powders or granular solids gently via a charging port or manhole. Never dump heavy or sharp-edged solids directly onto the glass surface. Use a protective liner or bag if necessary.

Liquids: Pump liquids through dip pipes or bottom valves. Control flow to avoid splashing.

Fill Limit: Do not exceed 70-75% of the total vessel volume to allow for adequate headspace and prevent boil-overs.

Temperature Control:

Heating/Cooling Rates: Limit jacket temperature changes to a maximum of 50-60°C per hour to prevent thermal shock to the glass. Use gradual ramps for programmable controllers.

Avoid Dry Heating: Never apply heat to an empty jacket. Ensure the vessel contains sufficient liquid to cover the heated surfaces.

Agitation: Start the agitator before beginning to heat viscous or slurry batches to prevent settling and localized overheating.

Pressure/Vacuum Operation: Always operate within the Maximum Allowable Working Pressure (MAWP) and vacuum rating. When applying vacuum, do so gradually.

Phase 3: Discharging and Cleaning

Post-Reaction: Cool the batch to a safe temperature and release any pressure before opening.

Discharge: Use the bottom outlet valve. If clogged, use gentle rodding with a soft plastic or wooden tool—never metal.

Cleaning: Use soft brushes and non-abrasive cleaners. For chemical cleaning, strictly avoid hydrofluoric acid-based solutions. Rinse thoroughly.

Critical Safety Protocols (The "NEVER" List)

NEVER subject the reactor to rapid temperature shock (>120°C difference).

NEVER strike or scrape the glass surface with metal tools or allow hard objects to fall inside.

NEVER introduce hydrofluoric acid (HF) or hot, concentrated phosphoric acid.

NEVER exceed the stated design temperature (typically 200°C) or pressure.

NEVER operate the agitator if it is hitting an internal component.

NEVER continue using a reactor with exposed metal (glass chip). It must be repaired immediately.

Conclusion

Operational

discipline is non-negotiable for GLS reactors. Comprehensive training

on this SOP and the "NEVER" list is essential for all personnel. By

treating the glass lining with care and respecting its physical limits,

users ensure decades of safe, reliable, and cost-effective service.