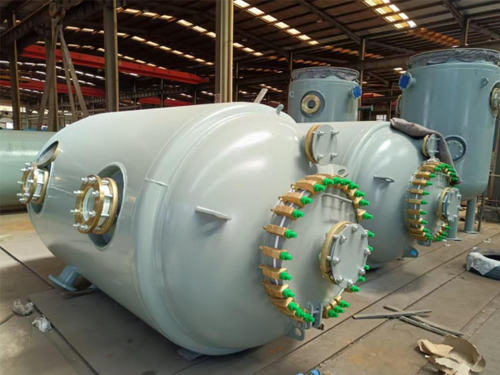

A Technical Guide to Specifying and Sizing Glass-Lined Reactors

Introduction

Selecting

a Glass-Lined Steel (GLS) reactor is a technical exercise that

translates process requirements into precise equipment specifications. A

well-specified reactor ensures optimal performance, safety, and return

on investment.

Step 1: Define Core Process Requirements (The Input)

Process Chemistry:

Full MSDS Review: List all chemicals, intermediates, and by-products. Flag any fluorides or strong alkalis.

Corrosivity: Define the type, concentration, and temperature of all acids, bases, and solvents.

Physical Properties: Note viscosity, presence of solids, abrasiveness, and foaming tendency.

Operating Envelope:

Temperature: Minimum and maximum process temperatures, and required ramp rates.

Pressure: Maximum operating pressure (positive or full vacuum).

Production Data:

Batch Size: Determine working volume, then select the nominal vessel size (typically 1.5x the working volume).

Duty Cycle: Number of batches per day/week influences mechanical seal selection and maintenance schedules.

Step 2: Determine Key Vessel Specifications

Design Pressure & Temperature:

The vessel's MAWP must exceed the maximum process pressure. Common classes: Full Vacuum, 6 bar, 10 bar, 16 bar.

Design Temperature must cover the full operational range, including cleaning cycles.

Heat Transfer Requirements:

Calculate the required heat transfer area based on the heat load (Q) and allowable time for heating/cooling. Standard jacket area may be insufficient; specify half-pipe coils, dimpled jackets, or increased surface area if needed.

Specify heating/cooling media (steam, thermal oil, chilled water) and corresponding nozzle sizes.

Agitation System:

Impeller Type: Anchor for high viscosity/heavy solids; turbine for gas dispersion; pitched blade for general mixing.

Motor Power: Size based on fluid rheology, impeller type, and desired tip speed. Oversizing is preferable to undersizing.

Step 3: Select Critical Configurations & Options

Sealing System:

Single/Double Mechanical Seal: Mandatory for vacuum, hazardous, or toxic services. Requires a support system (buffer fluid).

Gland Packing: Simpler, lower cost for non-hazardous, atmospheric pressure applications.

Nozzles and Connections:

Specify the number, size (DN), and location of all nozzles: manway, agitator, thermometer, sight glass, dip pipes, spray ball (for CIP), etc. Add spares for future flexibility.

Internal Attachments:

Ensure baffles, thermowells, and dip pipes are also glass-lined. For specific applications, PTFE-coated or solid PTFE components are available.

Guidelines for a Successful Specification

Collaborate Early: Engage with GLS manufacturer engineers during the design phase. Provide a detailed Process Data Sheet.

Build in Margin: Add 10-20% margin to calculated volumes, heat transfer areas, and motor power for process flexibility and future needs.

Cost vs. Risk: Invest in higher-pressure ratings and mechanical seals for hazardous processes. Do not compromise on safety-critical specs.

Think Systematically: Consider the reactor as part of a system including condensers, receivers, and transfer pumps. Ensure compatibility.

Conclusion

Proper

specification is the foundation for a successful GLS reactor

installation. A methodical approach that rigorously documents process

needs and translates them into precise engineering parameters results in

a vessel that is not just a container, but a optimized and integral

part of the production process.